Front brake calipers refurbishment on Austin Mini

Vehicle ➔ Mini 1000 year 1988

Difficulty ➔ Medium

Time ➔ 2 hours

Summary

Are the brake caliper pistons oxidized ? Is it impossible to push them back into their housings when changing the brake pads ? It's time to refurbish the brake calipers.

Refurbishing a brake caliper is not complicated. Just be rigorous and meticulous to get a good result.

There are aftermarket brake calipers available. However, a repair kit will be much cheaper than a new caliper.

Don't hesitate to buy good quality components, especially for seals and retaining rings. Assembly will be much easier.

The new caliper pistons (114713) used in this tutorial are made of stainless steel. They will have a significantly longer lifespan than the original pistons.

Brake fluid is extremely aggressive with paint. Be careful not to spill any on the bodywork. Clean any stain immediately with a cloth and water.

Safety

Throughout the caliper refurbishment, be careful not to allow any impurities to enter the hydraulic brake system. This could impair its proper functioning.

It is strongly discouraged to separate the 2 halves of the caliper :

• Firstly because it's unnecessary. The pistons and seals can be changed while the caliper is assembled.

• But also because the temperatures reached during braking may have slightly deformed the joint faces of the halves. If this is the case, during reassembly, the seal between the two halves would not be guaranteed.

• Firstly because it's unnecessary. The pistons and seals can be changed while the caliper is assembled.

• But also because the temperatures reached during braking may have slightly deformed the joint faces of the halves. If this is the case, during reassembly, the seal between the two halves would not be guaranteed.

Packaging :

•

114713 : Piston sold individually. There are 2 pistons on each caliper.

• GFK1126 : spring washer sold individually.

• GRK5008 : Seal kit for the 2 pistons of one caliper (2 seals + 2 dust seals + 2 retaining rings).

• GFK1126 : spring washer sold individually.

• GRK5008 : Seal kit for the 2 pistons of one caliper (2 seals + 2 dust seals + 2 retaining rings).

Advertisement

Remove the LH front caliper

Op 01

Remove the wheel and the brake pads (➔ see the tutorial ''Front brake pads change'' Op 01 to 06).

Op 02

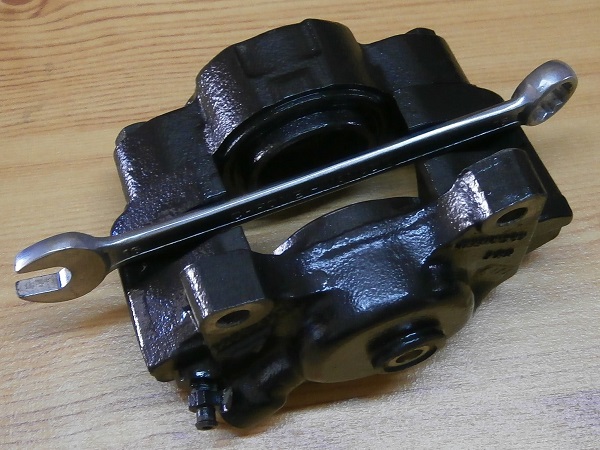

Loosen the brake hose slightly. Use the 15 mm spanner.

This operation is easier to perform when the caliper is attached to the swivel hub.

Op 03

Remove the 2 brake caliper fixing bolts. Use the 14 mm socket.

Op 04

Unscrew and detach the hose from the caliper by pivoting the caliper on itself.

This method avoids twisting the hose.

Place a drain pan under the caliper to collect the brake fluid.

Refurbish the caliper

Op 05

Thoroughly clean the brake caliper. Use brake cleaner.

Position a shim between the two pistons of the caliper (piece of wood or other).

Op 06

Using an air compressor, blow into the brake fluid inlet orifice to eject 1 of the 2 pistons.

Do not put your fingers between the 2 pistons when you eject them because they will come out violently.

Place the caliper above a drain pan as the brake fluid remaining in the caliper will drain.

Op 07

Recover the piston that has been ejected.

Op 08

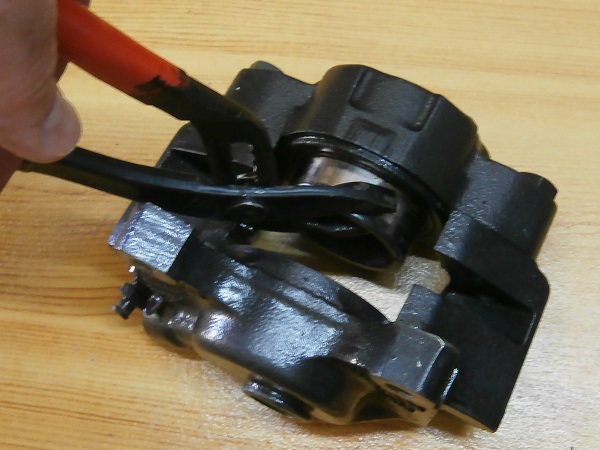

Remove the 2nd piston. Use the multigrip pliers.

This is when it gets a little complicated because generally the piston doesn't particularly want to leave its nest. Rotate it several times on itself and it will eventually come out.

Op 09

Remove the dust seal and its retaining rings. Use a large flathead screwdriver.

The effort to be exerted is significant. If necessary, immobilize the caliper in a vice.

Op 10

Remove the seal. Use a small flathead screwdriver.

Be careful not to scratch the inside of the caliper. This could impair the sliding of the piston.

Op 11

Remove the seals and retaining rings from the 2nd piston. Proceed in the same way.

Op 12

Lubricate the new seal (kit GRK5008) with brake fluid.

This is the rectangular section seal.

Op 13

Position the new seal in the groove.

This seal is symmetrical. There is no direction to respect during installation.

Position this seal only with your fingers. Do not use any tools as you could damage it.

Sometimes the seal twists during assembly. Once the seal is in place, run your finger over its entire circumference to check that it is in position.

Op 14

Lubricate the new piston (114713) with brake fluid.

Op 15

Insert the piston into the caliper.

The hollow part of the piston must be positioned on the brake pad side.

Let the piston protrude by approximately 8 mm (2nd photo). It will ensure the guiding of the dust seal and its retaining ring in their housing.

Op 16

Lubricate the dust seal (kit GRK5008) with brake fluid.

This is the lip seal.

Op 17

Fit the dust seal onto its retaining ring (kit GRK5008).

This seal is symmetrical. There is no direction to respect during installation.

Op 18

Position the dust seal and its retaining ring on the piston.

The folded edge of the retaining ring must be positioned on the brake pad side.

Op 19

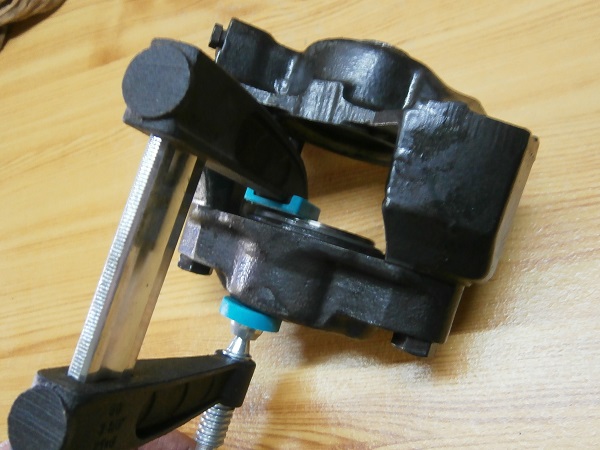

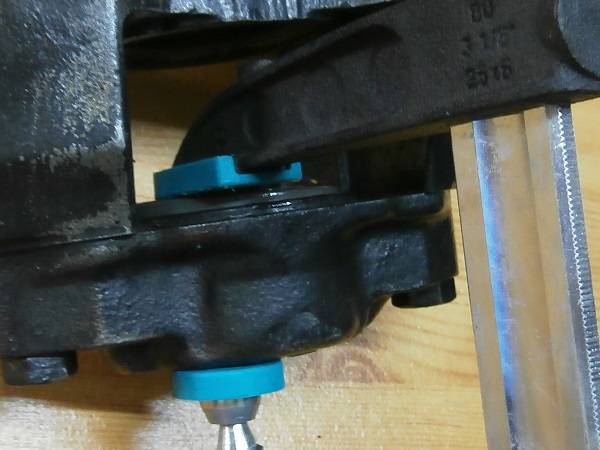

Push the dust seal and its retaining ring into their housing. Start by hand and finish with a clamp if necessary.

The retaining ring is mounted slightly forcefully in its bore (it is thus held in position). But this retaining ring is also extremely fragile. So you have to force it a little to get it in, but not too much to avoid deforming it. It's up to you !

Op 20

Position the second piston and its seals. Proceed in the same way.

Clean up any brake fluid spills on the caliper.

Advertisement

Fit the caliper

Op 21

Screw the hose onto the caliper by pivoting the caliper on itself.

This method avoids twisting the hose.

Op 22

Fit the caliper on the swivel hub.

Screw the 2 caliper fixing bolts with their spring washers (GFK1126). Use the 14 mm socket.

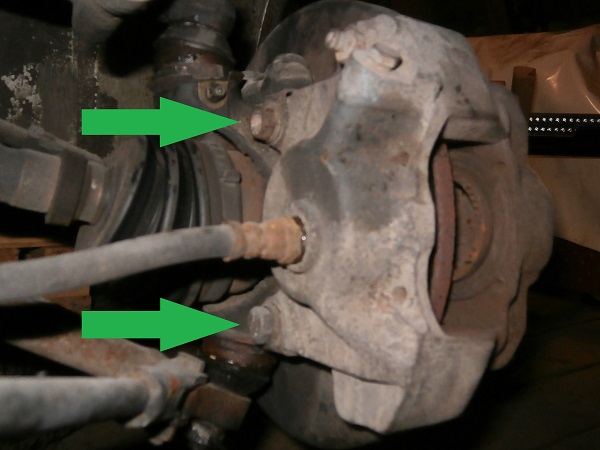

When reassembling the calipers on the Mini, be sure to position the RH caliper on the RH wheel and the LH caliper on the LH wheel. Here is a very simple method to check that the assembly is correct : the bleed nipples must be located in the upper part of the calipers (see circled in the 2nd photo).

If the calipers are swapped and the bleed screws are at the bottom, bleeding the brake circuit will not be correct. Air will remain in the calipers and braking will be ineffective.

Op 23

Tighten the 2 caliper fixing bolts to a torque of 52 mN. Use the torque wrench and the 14 mm socket.

Op 24

Tighten the brake hose on the caliper. Use the 15 mm spanner.

Op 25

Fit the brake pads and the wheel (➔ see the tutorial ''Front brake pads change'' Op 10 to 16).

Advertisement

Refurbish the RH front caliper

Op 26

Refurbish the RH front caliper. Proceed in the same way.

Bleed the brake system

Op 27

Bleed the brake system (➔ see the tutorial ''Brake system bleeding'').

The End